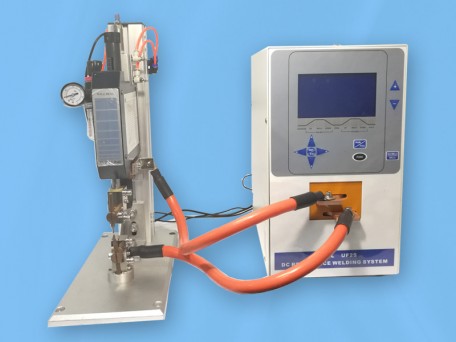

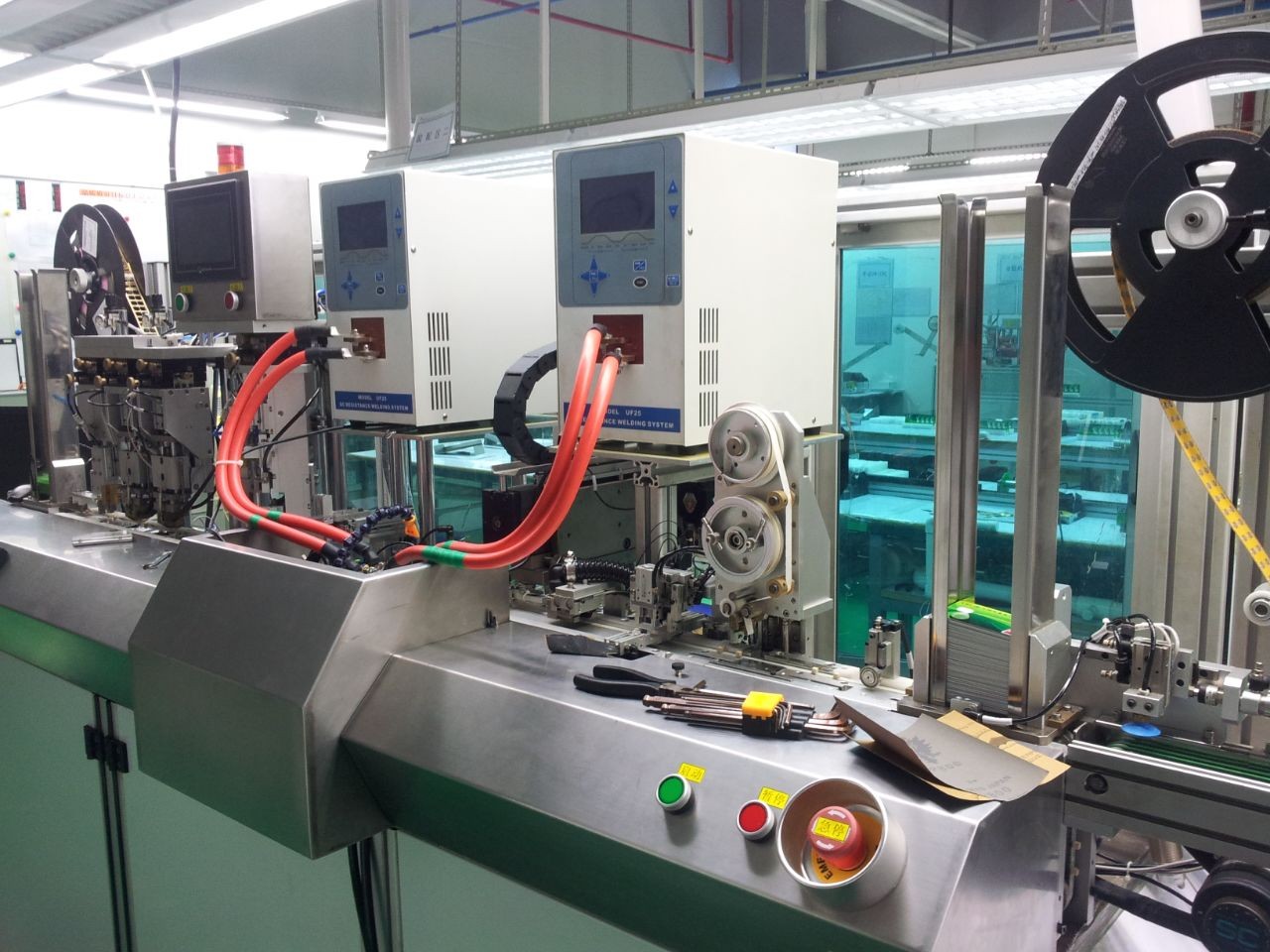

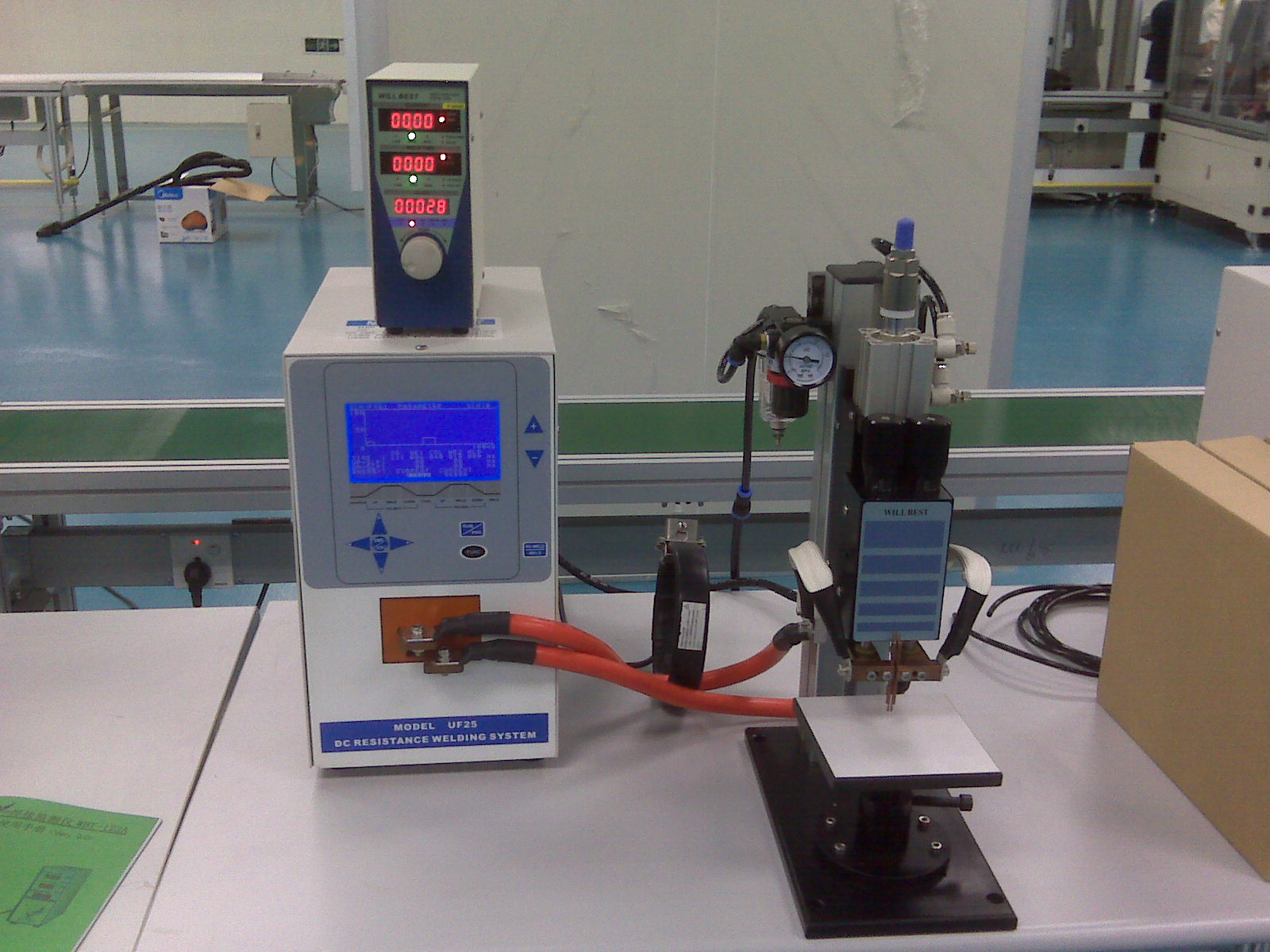

Wire & Metal Sheet & Enameled Wire Spot Welding Machine

CE CERTIFICATION

Videos:

https://youtu.be/pqd5HKokYKM

https://youtu.be/5qq6DdultOU

https://youtu.be/QZWciVmdSh8

UF25 Features:

High inverter frequency makes the control of welding energy more accurate and rapid.

With double pulse welding function.

Each pulse has the functions of slow rise, slow fall, welding time, welding energy and monitoring data setting.

A variety of welding energy control modes, constant current / constant voltage / constant power, to meet the welding needs of different shapes of materials

Various welding working modes, ordinary spot welding, roll welding / seam welding, continuous welding, double welding head control, PLC control.

The welding results are displayed in text and graphics, which makes the debugging more intuitive and simple.

It has the function of welding quality monitoring and result output, and automatically detects unqualified products.

Serial communication function.

WBT-Q01 Specifications:

1. Net weight:10KG

1. Net weight:10KG

2. Size: 320mm*180mm*450mm

3. Spring force:0-8kg

4. Thinline:145mm

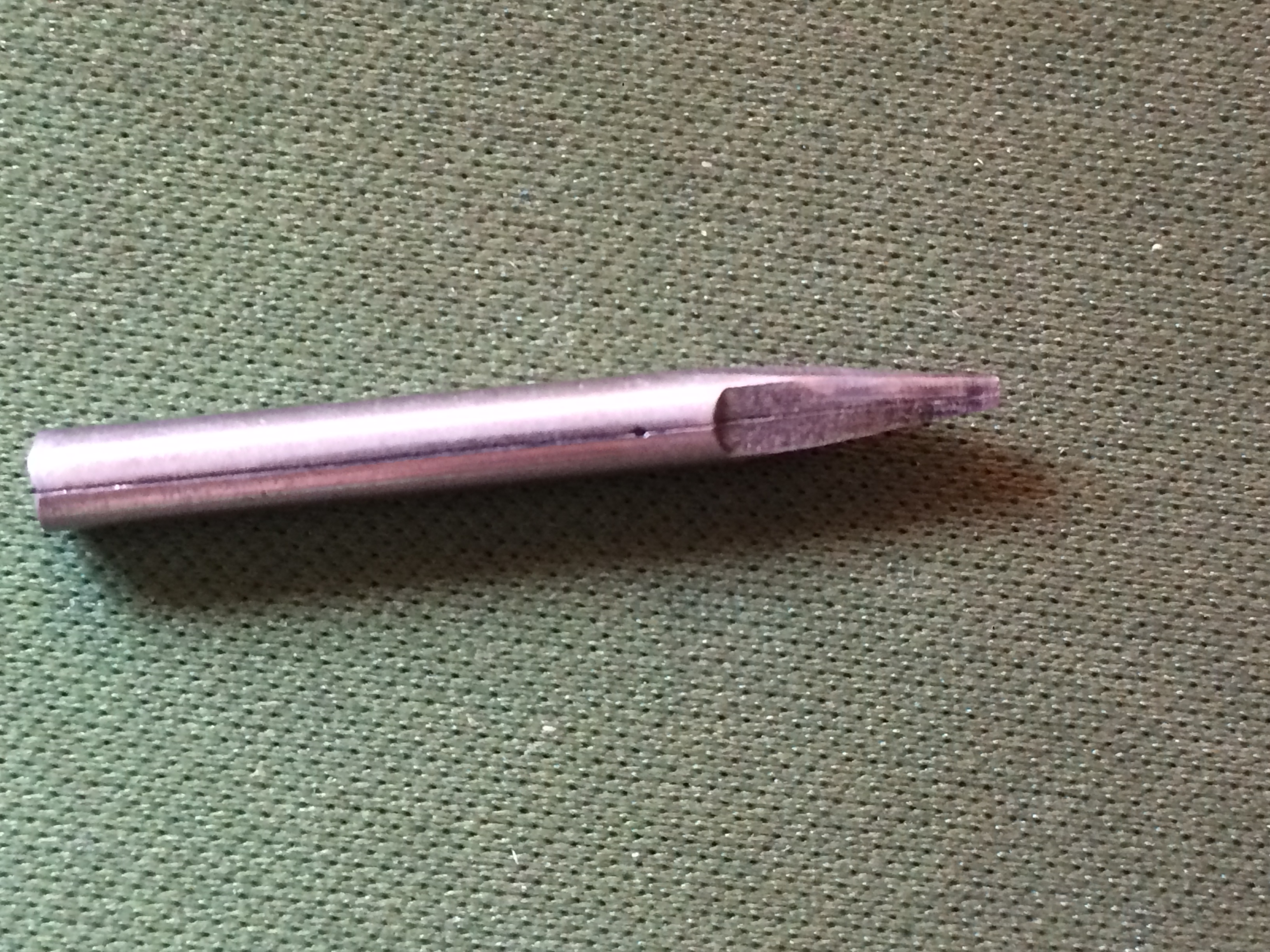

5. Electrodes:3mm/6mm(diameter)

6. Driving method: Pneumatic

7. Magnetic valve:24V(DC)/220(AC)

When the marterial is high conductive(such as copper,brass) the marterial of electrodes

need to using poor conductive(such as tungsten, molybdenum,tungsten copper)

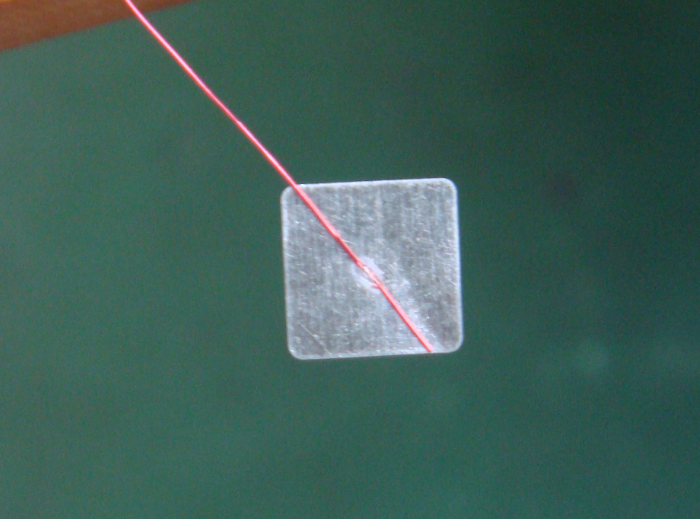

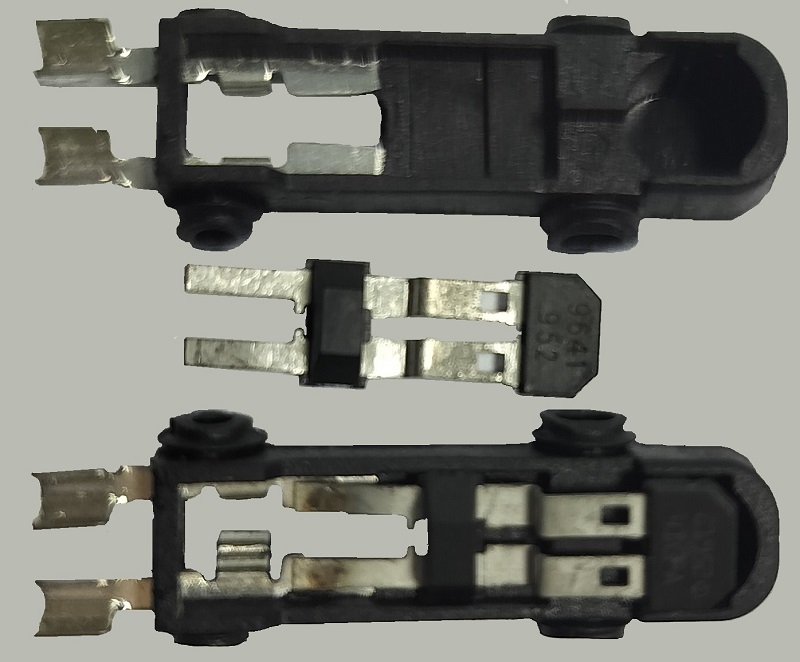

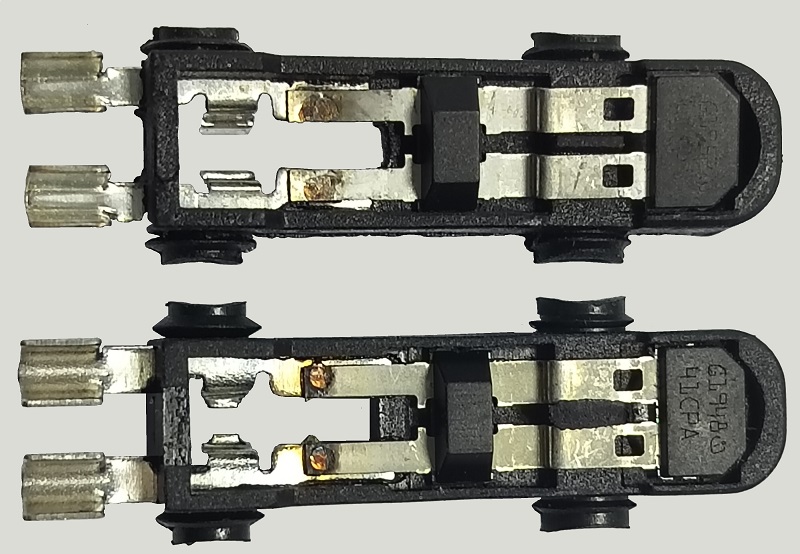

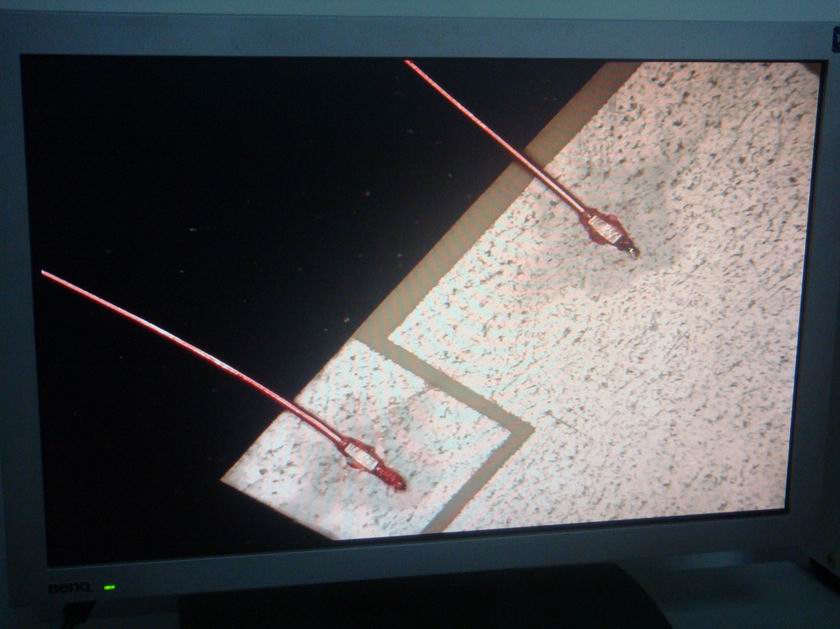

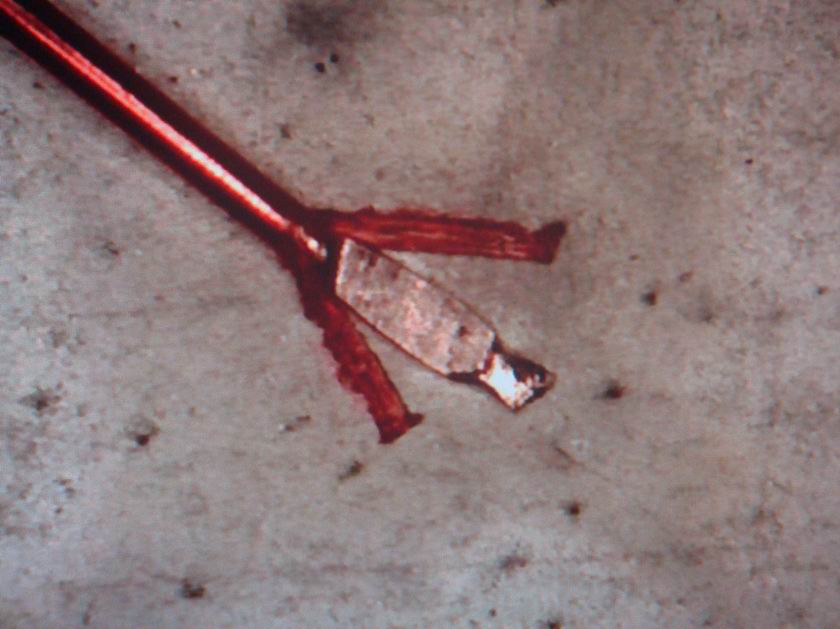

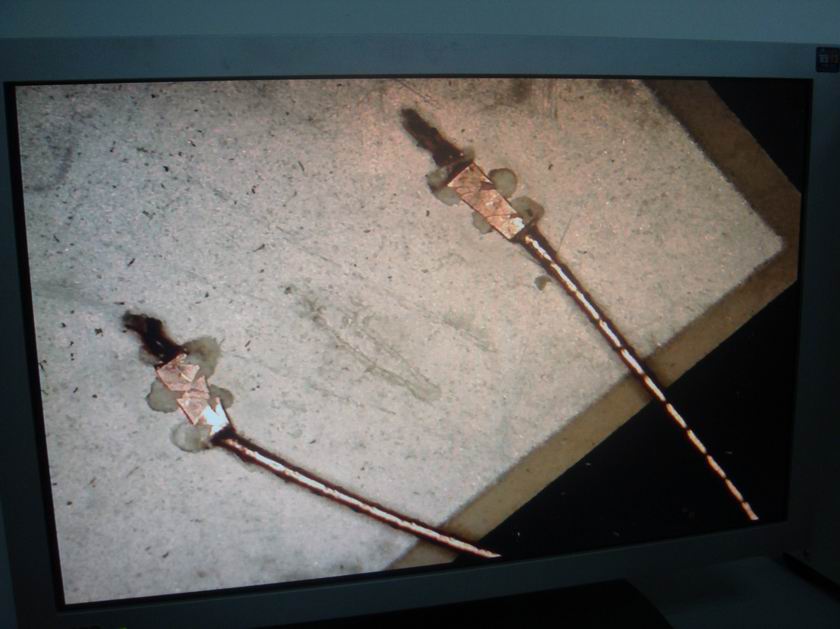

Welding Samples: