Welding Heads

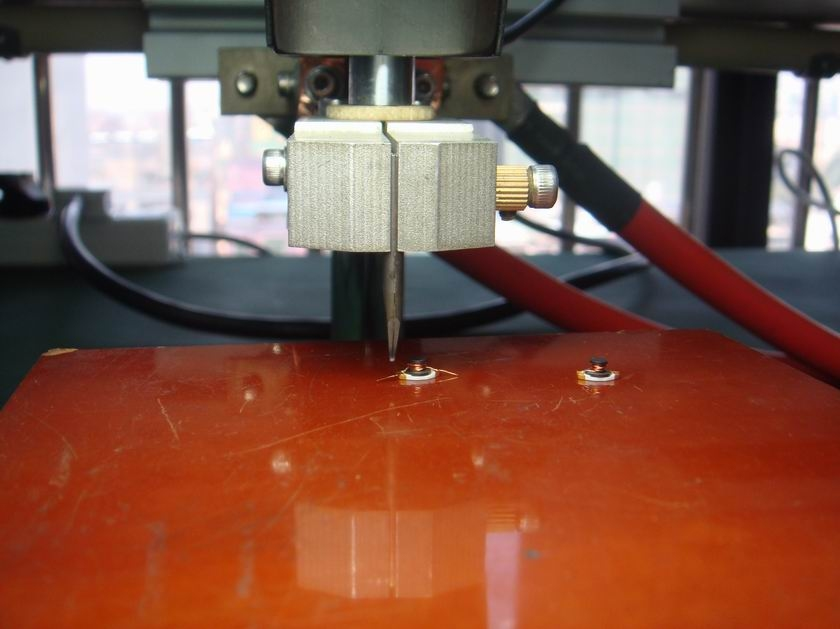

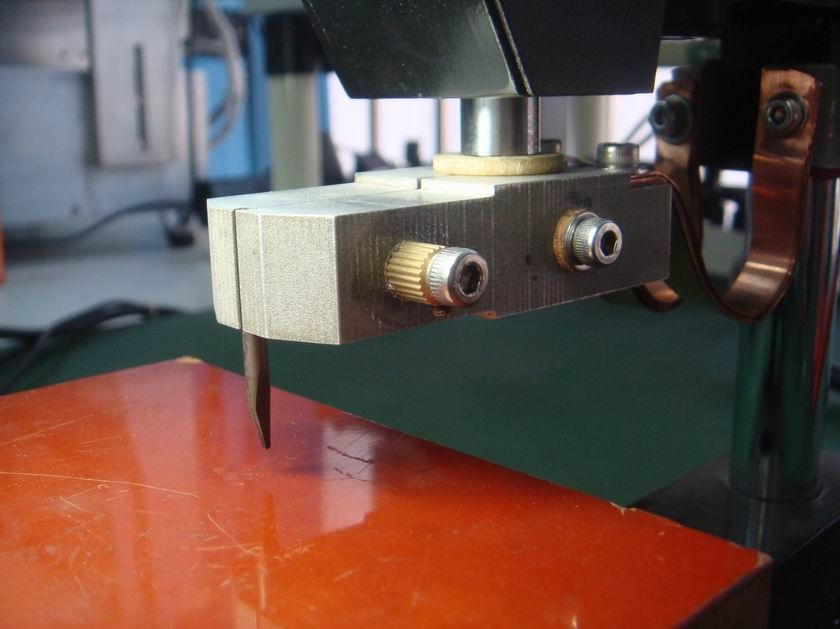

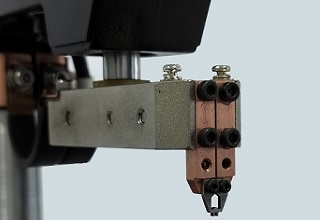

WBT-F01 Mechanical Precision weld heads

Features:

1. Application-specific modifications available

2. Outstand dynamic response

3. Outstand follow-up properties

4. Short welding time

5. Foot pedal mechanical drive electrodes

6. Build in welding force swtich

7. Provide stable weling force through springs

8. Adjustable electrode stroke

Product Details

Specification:

1. Net weight: 10KG

2. Dimension: 348mm x 193mm x 43mm

3. Welding force: 0.4KG - 10KG

4. Throat depth: 145mm

5. Electrodes: 3mm/6mm(diameter)

6. Driving method: Foot pedal

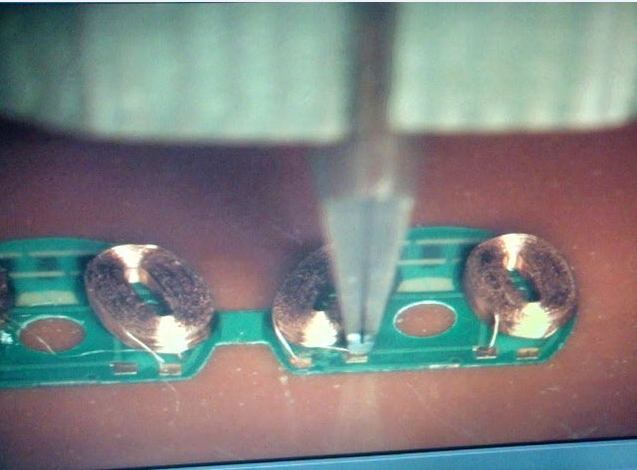

Applications:

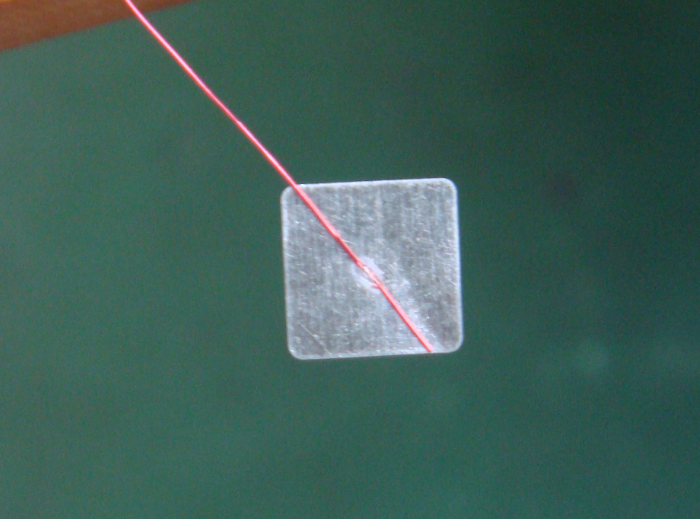

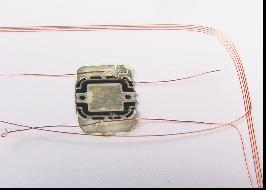

Weld the Copper wire,need use the difference electrodes and holders