Wire & Metal Sheet & Enameled Wire Spot Welding Machine

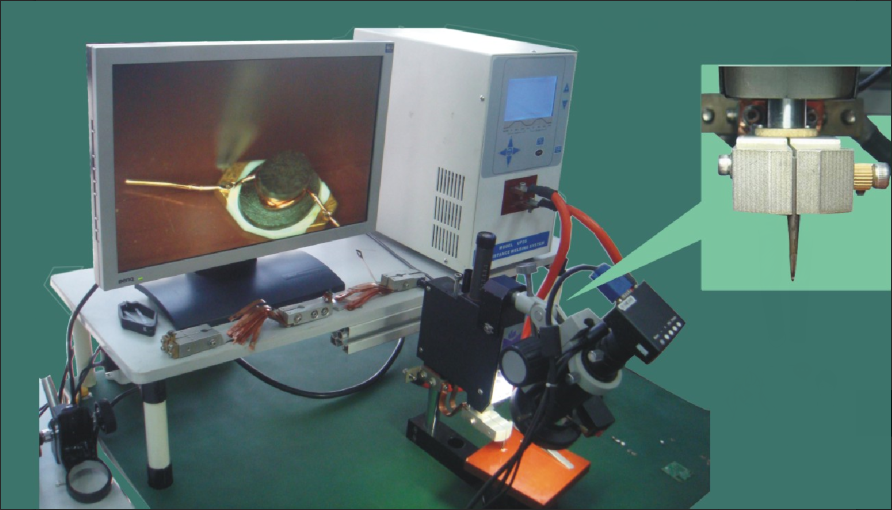

Kit Introduction:

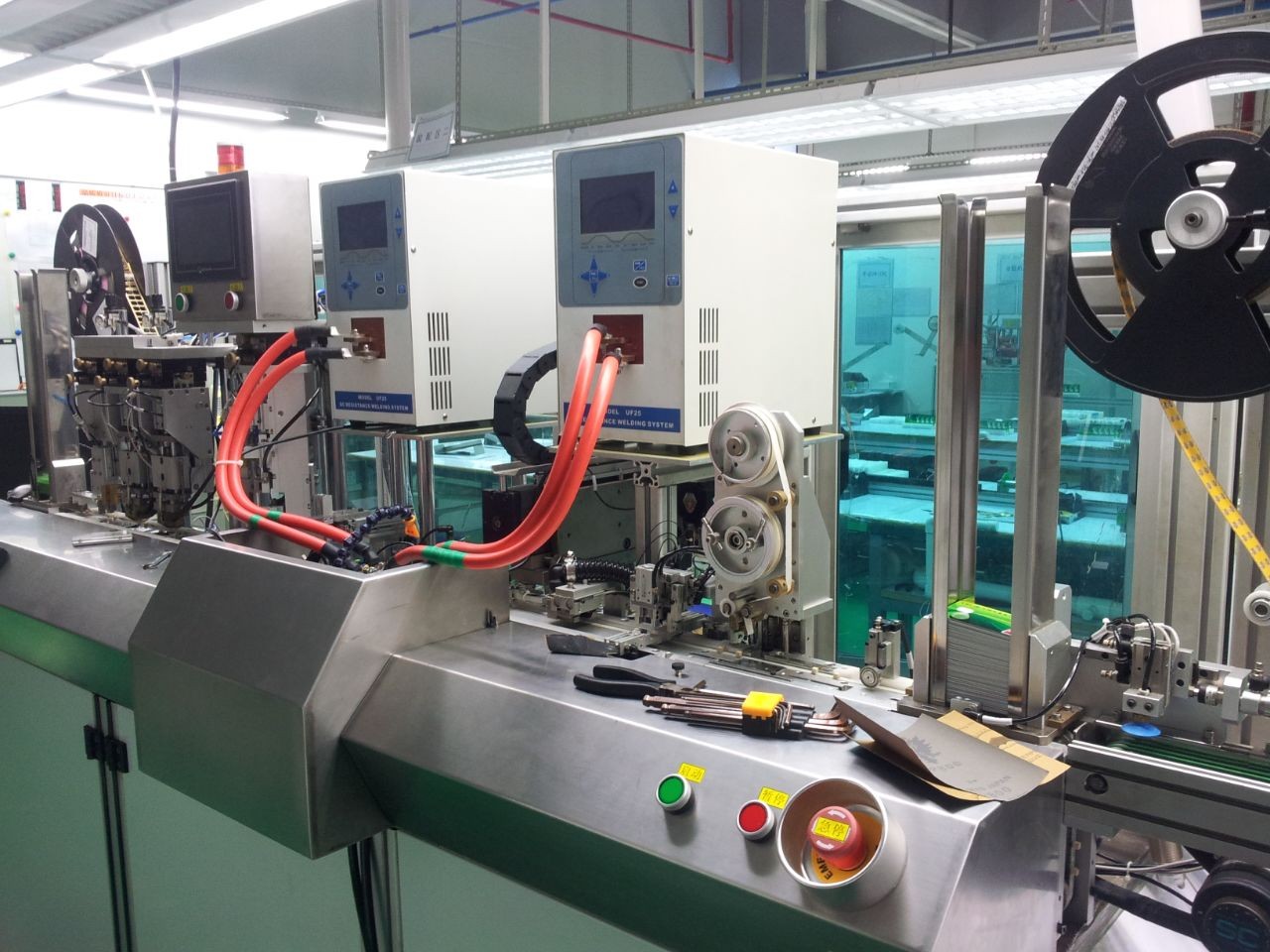

1.UF25 weld power supply

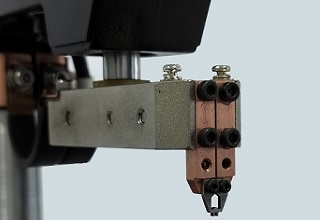

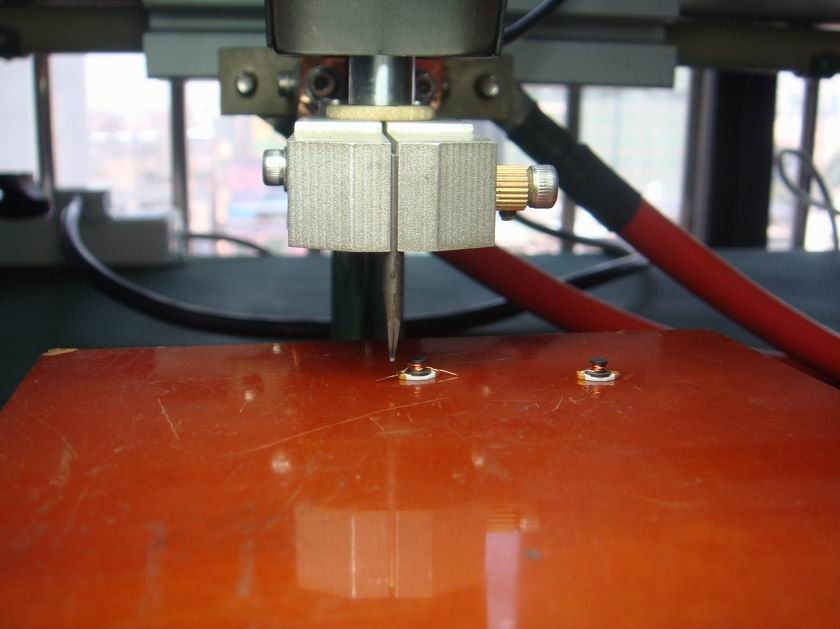

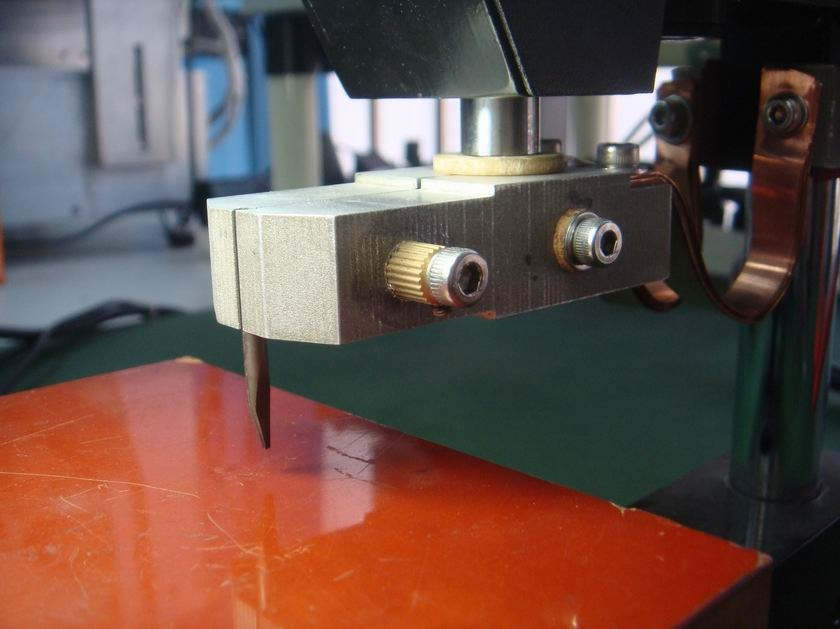

2.WBT-F01 weld head

3.HD video microscope

4.Display screen

5.Needle type electrodes

UF25 Features:

1. High inverter frequency makes the control of welding energy more accurate and rapid.

2. Dual pulse welding function.

3. Multiple welding energy control method: constant current/constant voltage/constant power

4. Multiple welding modes can be suitable for various welding applications

5. The welding result datas can be sent to the computer throught a serial port

WBT-F01 Specifications:

1.Size: 348 x 193 x 430mm

2.Weight: 10kg

3.Fire method: Micro switch

4.Electrode modified for specific applications

5.Welding force range: 15N — 89N

6.Throat depth: 125mm

7.Driving method: by foot

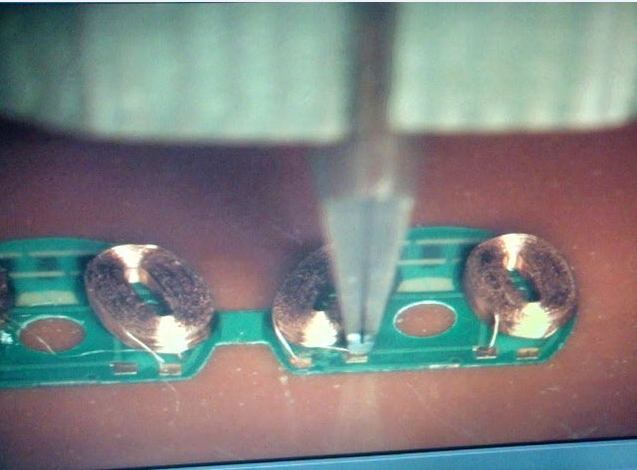

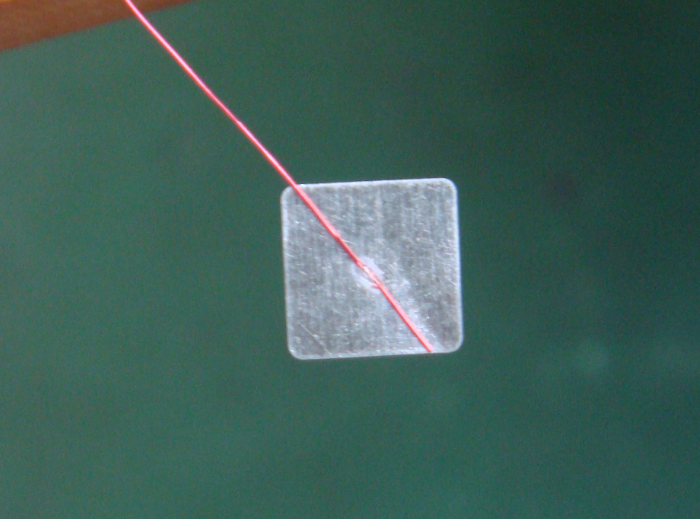

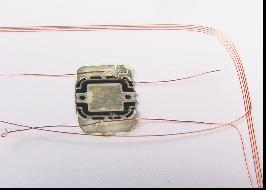

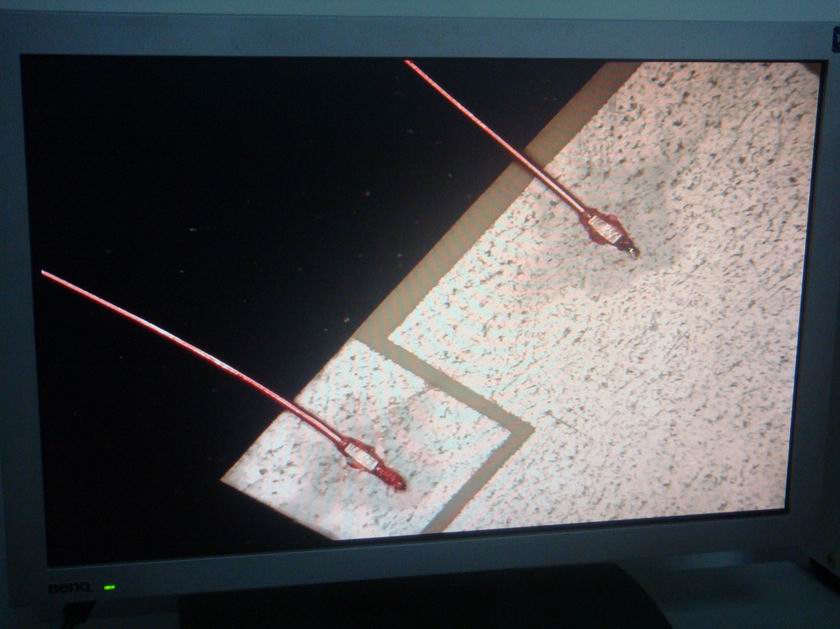

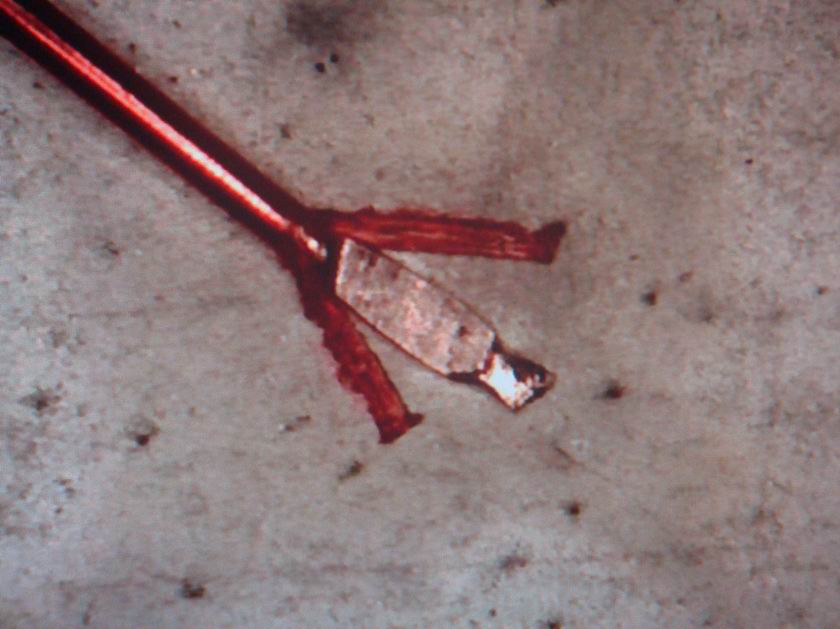

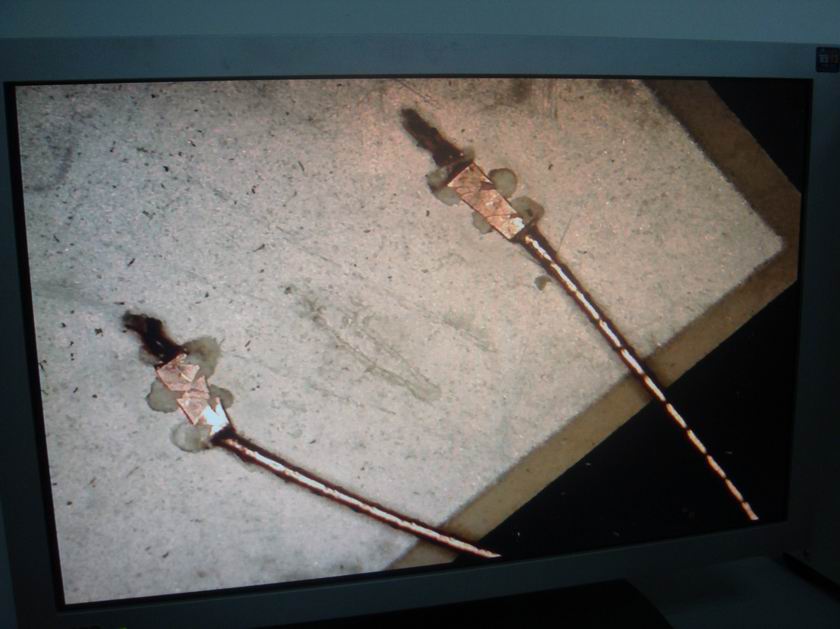

Welding Samples: